A Visit to the Synthetic Cadaver Factory

Florida’s SynDaver Labs makes extraordinarily advanced anatomical models.

In an ordinary Tampa, Florida, office park, just a couple of blocks from a bustling thoroughfare, a skinless cadaver named Quella is having the muscles of her arms individually sewn together by a young woman wearing headphones and a hoodie.

On a table nearby, a technician lays out an exposed vascular system, pushing water through it until she finds a leak that sprays like gore from a PG horror movie.

It’s not quite lunchtime at SynDaver Labs. Inside this otherwise unassuming facility, workers are creating what may be the world’s most advanced surgical and anatomical models out of little more than salt and water. Fully synthetic corpses like these, complete with skin, muscle, organs, and bone, might one day eliminate our need to test many new technologies on humans or animals.

And it’s not just SynDaver’s materials that make their cadavers unique. It’s their visceral realism.

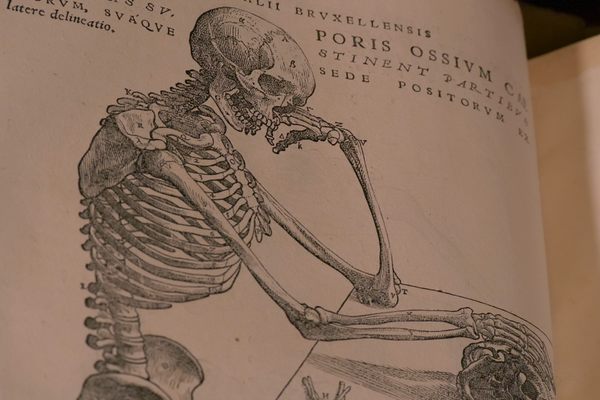

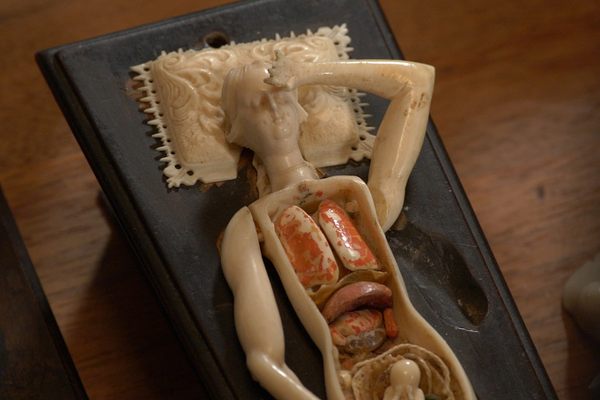

Anatomical models have existed for centuries, as attempts to recreate biology, as training tools, and as living records. Museums across the globe hold generations of anatomical reproductions made of everything from wax to plastic to real bone. Many of them, having been created in less learned times, look odd or monstrous to us now, but they’ve all been stepping stones on our journey toward more comprehensive and humane ways of learning about physiology.

SynDaver’s products carry on that legacy into realms that are both gruesome and fascinating. “It’s about creating empathy,” says Dr. David Danielson, the company’s vice president of veterinary technologies. Danielson joined the team about a year ago to help develop a new canine model. Part of SynDaver’s stated goal is to provide a synthetic training experience for the medical fields that feels as emotionally real as working with an actual dead thing. Danielson says he’s seen this in action, when some students he was working with ruptured one model’s pumping artery, releasing a stream of fake blood. “I want them to fail. They took it seriously. They were shaken, they were nervous,” he says. By making mistakes on SynDaver’s fake bodies and organs, the thinking goes, students can better prepare themselves for the unforeseen crises that can pop up with real patients.

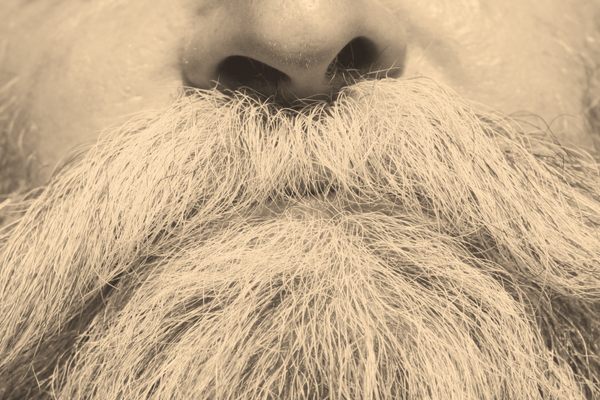

SynDaver’s founder and president, Dr. Christopher Sakezles, is not a medical doctor. Sitting in his office, he looks every bit the slightly eccentric mastermind of a body factory. Wearing blue medical scrubs embroidered with the SynDaver logo, he’s surrounded by toys, and magazines about military miniatures. With a background in polymer science and engineering, Sakezles started SynDaver following a career in the medical device industry. “It actually started in grad school,” he says. “I was developing a new kind of endotracheal tube, and we didn’t have enough money to run an animal study.”

Looking for a stand-in trachea, his professor ordered a model that Sakezles describes as “absurd.” Simply a plastic tube with some coiling around it, the training organ neither looked nor functioned like a real piece of anatomy. “I threw it in the trash.” Sakezles then went ahead and built his own trachea model using a material of his own design, and the die was cast. He could do better.

The earliest incarnations of SynDaver Labs date to 2004 in Princeton, New Jersey. Sakezles spent the first five years working alone on basic research, filing patents, and perfecting the proprietary formula of salt, water, and fibers that make his synthetic humans so eerily life-like. In 2009, he hired his first employee and launched the Tampa operation. Eventually bringing on outside investors (a period of time that resulted in an abortive appearance on Shark Tank), the company continued to grow, but it hasn’t been an easy road. “I can’t tell you how many investors have insisted that we start making sex dolls,” Sakezles laughs.

Today, SynDaver Labs employs around 100 people, and takes up nearly every inch of their office park with the various steps along their synthetic body assembly line. SynDaver’s flagship product is their full cadaver, which is available in differing levels of interactivity. “It’s like a Chevy you can turn into a Cadillac,” says Sakezles. They also sell dozens of synthetic organs and targeted task trainers, such as a replica of a back that’s optimized for practicing spinal taps, or a wearable piece of torso for chest tube training. If you need a body part, SynDaver can build it.

Sakezles has continued to develop his false flesh into over 100 variants, whether for skin, muscle, or vein. Looking in part to help reduce the number of cats used in medical training (yes, this is a thing) as well as to provide an option for veterinary interests, the company has recently introduced a synthetic dog to their catalog, with a cat and a horse also in the works.

SynDaver sells about 100 full-body synthetic cadavers a year, and they aren’t cheap. Their lowest end “mortuary science” model goes for about $50,000, while the most expensive body they’ve ever sold went for a whopping $184,000. At first glance, the price seems prohibitive compared to a real cadaver, but “it’s not really a fair direct comparison,” Sakezles says. “Cadavers in some cases are free to acquire. But then you have transport costs and disposal costs and handling costs and facilities and all the regulations. You have to build a $4 million facility to use a cadaver. With a SynDaver you just need a table.”

In the early days of the company, each piece of SynDaver anatomy was modeled by hand, out of clay or wax. Today they’ve mostly moved on to 3D modeling, but their development space still retains the marks of the old days. Splotches of clay drippings cover the checkerboard floors, and every surface is cluttered with half-created prototypes of bones and body parts.

The designers and artists developing SynDaver’s products are surrounded by scraps, sketches, reference materials, fake bones, sculpting tools, random body parts, and tissue made of plastic and clay. One worker stands at a table painting metal rods with a clear substance he’s dabbing out of a crock pot, developing custom veins for a customer; another sits at a computer, modeling a cat’s rib cage for a forthcoming “cat-in-a-bag” product, which will allow trainees to reassemble a synthetic cat, as opposed to taking it apart. “We’ve learned that building anatomy is the best way to learn it,” says Sakezles.

There’s a small room crammed with half-a-dozen 3D printers, working 24-hours-a-day to pump out prototypes. A rib cage being slowly constructed in white plastic looks like a scene straight out of Westworld. Sakezles says they’re also trying to develop a way to print wet tissue.

The actual construction of the products takes place across a handful of stations throughout the complex. The body parts begin life in a large manufacturing room, with rows of tables where workers sit, adding detail and color to raw material molds. Each of the fabricators has a specialty. One woman delicately lays pieces of red string, meant to indicate part of the vascular system, into what looks like it will eventually be a lung. At another station, someone is painting a pink hue into what will be a dog’s ear.

A majority of the staff at SynDaver, a mix of young to middle-age employees, some sporting mohawks and piercings, wear surgical scrubs. “It’s messy work,” says Sakezles.

On one end of the manufacture room stand racks of molds for all of the separate parts needed to create a single synthetic cadaver. Against another wall is a row of foil-lined crock pots that hold different consistencies of material, ready to be applied to the appropriate mold. The entire facility is infused with the smell of the company’s signature material—a salty, slightly antiseptic scent that sticks to the skin long after touching the stuff.

Depending on the intended use of a specific SynDaver, each comes equipped with varying levels of complexity. Some are cosmetically accurate models, with all the muscles and organs. Others can bleed, simulate breathing, and even “go into shock” with the help of sensors and pumps.

Full-body SynDaver humans are put together in a final assembly room across the complex, where each muscle and organ is hand-sewn together, piece by piece, and working systems are tested before being added. Nearly complete, skinless cadavers are laid out on tables, their extremities propped up on yoga blocks, as seamstresses expertly join biceps, hands, and buttocks to a plastic skeleton frame (hello again, Quella). Pin cushions and other traditional sewing equipment litter the tables next to frighteningly realistic pieces of SynDaver meat.

On another table, a functioning vascular system is spread out and tested for leaks. Pump boxes underneath the table push water through a synthetic heart and down its fibrous veins. Spurts of water begin to gush in a natural rhythm down what will be a right leg, spraying out of a small tear near the end of the line—a technician notes that it will have to fixed before it is installed. The scene is somewhere between a futuristic mortuary and an underground clone factory.

This is also where SynDaver’s synthetic humans come to be repaired and serviced. All SynDaver cadavers come with a service agreement that usually covers replacement parts. If you are a medical school that uses a surgical SynDaver model, and students are cutting into parts and damaging them, you can send your body back, and it will be repaired piecemeal, to be put under the knife once again. With the proper care, Sakezles says that his company’s synthetic bodies can pretty much last forever.

The walls are lined with metal racks full of plastic bins, each of which hold a specific part needed to build a synthetic human or animal. Labeled with painter’s tape and marker, there’s a bin for stomachs, one for vaginas, one for spleens, and on and on. SynDaver material, made of 85 percent water (much like a real human being) needs to be stored in water or else it will dry out, so each of the bins is filled with a level of liquid that the spare parts float in. Hilariously horrific dried-out abominations can be found all over the room, like grim reminders that the parts need to be hydrated.

When a completed body, or say, a head, is finished, they too need to be stored in water until they are shipped out, so one end of the finishing room is home to rows of large green vats full of realistic-looking synthetic bodies. Arguably the most unsettling location in the lab, the tubs hold such wonders as a half-human with full skin save for its midsection, with intestines floating out of the body. There are also finished editions of the new canine trainers, plus various component parts—doggo heads and muscles, bumping together in the water.

Since each handmade synthetic cadaver is unique to some degree, they’re not given serial numbers but names, which are recorded on ankle bracelets. Sakezles says that anything with a head gets a name, including the dogs. One canine vat holding a pair of dogs indicated that they were “Wynonna” and “Jazzy.” There’s no hard and fast system for naming a SynDaver cadaver. One employee mentioned that they frequently turn to the internet for inspiration, having already burned through the names of Game of Thrones characters. Otherwise they just go down the alphabet to make sure they don’t repeat themselves.

Once a synthetic cadaver is ready to be shipped, they’re sealed, placed in standard body bags, and sent off in militaristic plastic crates that double as their storage boxes.

Thanks to their portability, the amazingly lifelike nature of the SynDaver material, and their complex construction, the company’s products are finding a growing number of applications. In addition to their uses in medical training and experimentation, SynDaver has also been finding new customers in the automotive industry, TV shows such as Mythbusters and Grey’s Anatomy, and the Army’s Transport Medical Training Laboratory.

But even as the business expands, Sakezles would eventually like to get back to his original passion, developing medical devices, which thanks to SynDaver’s technology he says he can now do faster and more effectively.

SynDaver continues to evolve and improve their models, each time aiming to bring them closer to the physical and emotional experience of working with a formerly living being. But at this point Sakezles and his team are getting to a level of granular anatomy that’s hard to beat. “That is a process that will never end. Because we’re never going to get down to the level of individual cells unless we’re cloning people,” says Sakezles. “What we’re trying to do is impossible. But every day we get a little better.”

Follow us on Twitter to get the latest on the world's hidden wonders.

Like us on Facebook to get the latest on the world's hidden wonders.

Follow us on Twitter Like us on Facebook