The Iconic Windmills That Made the American West

They may look quaint, but these “wind engines” were innovative and technically profound.

The Mid-America Windmill Museum, in Kendallville, Indiana, exists almost entirely outdoors. Its 53 specimens, most of them metal, are dropped like jacks across a patch of grass a few miles north of State Road 3, and represent one of the largest collections of vintage American self-regulating water pump windmills anywhere.

You have probably seen windmills like these before, if not in person, then in pictures or on television. Sometimes known as “windpumps” or “wind engines,” they power a mechanical apparatus that draws water out of the ground. They share a general silhouette—reinforced tower, slatted fan wheel, rudder-like tail—and most are around forty feet high. They have names like Butler Oilmatic; Dempster 12A; Baker Direct Stroke; Southern Cross; The Whizz; Fairbury No. 33; Aermotor 602. In 2018, these windmills have a quaint, decorative sort of feel, like something you would find at an antique mall. But they are in fact technically profound pieces of equipment with a history of powering American expansion.

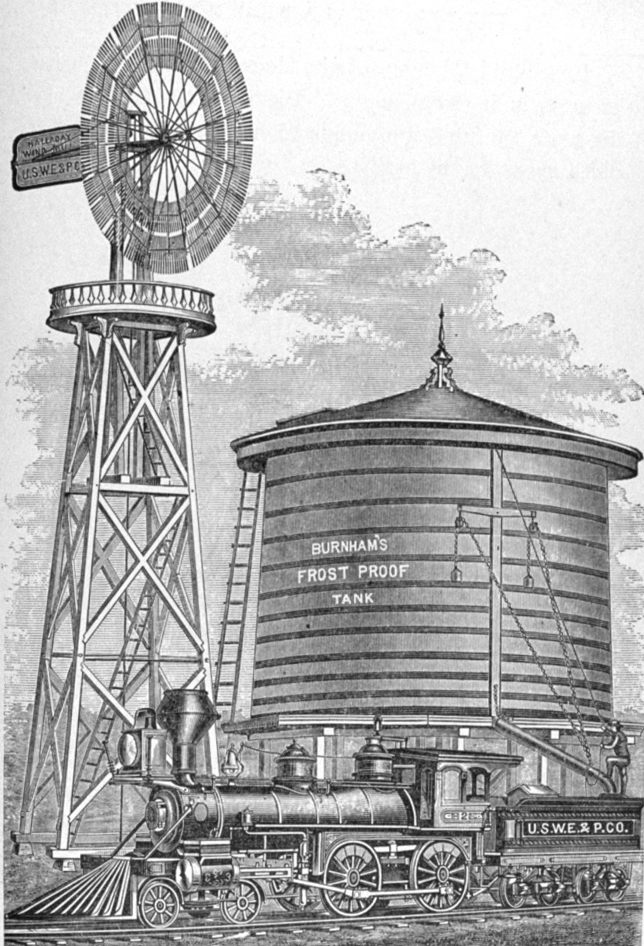

In A Field Guide to American Windmills, the historian T. Lindsey Baker writes that “the first commercially successful self-governing [or self-regulating] American windmill” was developed in New England in the mid-1850s, by a salesman named John Burnham and a machinist named Daniel Halladay. Unlike more traditional European-style windmills, The Halladay Windmill Company’s product was nimble; it could swivel to face the changing wind and angle its blades to adjust speed and avoid cracking in powerful gusts. Most importantly, it could do all of this mechanically, responding to the power and direction of the wind without the help of people.

It was a brilliant innovation, but the company was poorly located. Demand for water pumps was marginal in the stream-rich Northeast. The real action, Burnham and Halladay realized, was in the Midwest and West. Settlers lighting out to cover the prairies and flatlands of the country were in need of a reliable, independent water source. To better access these expanding markets, Burnham eventually moved the operation, now called the U.S. Wind Engine and Pump Company, to Batavia, Illinois, outside of Chicago.

Self-governing water pump windmills soon became a staple of the American homestead. They were simple, well-constructed, and dependable, the windmill equivalent of a pair of denim jeans. At first they were mostly wood, but metal varieties became more and more common. Almost every farm had one. Some people, unable to afford a professional windmill, fashioned their own using manufactured versions as models. According to an article in the journal Wind Energy, more than one million such windmills had been erected across the United States starting in the mid-19th century.

Railroads were another important customer. Steam locomotives had to be watered at regular intervals, which was accomplished with a string of tanks and pumps. On the first transcontinental railroad, tanks occurred about every twenty miles. Self-regulating windmills, some of which were also self-oiling, required little to no maintenance and could operate unattended, making them ideal for long stretches between towns. Manufacturers started putting out windmills that had wider bases and could pump greater quantities of water. These came to be called “railroad pattern” windmills. The most common version—and one of the biggest and most powerful—was called the Railroad Eclipse. Eventually, some communities used railroad pattern mills for municipal water supplies.

The primary element in a windmill water pump was an underground pumping cylinder fitted with a sort of plunger. As the plunger moved up and down, piston-like, it captured water (on the downstroke) and pulled it toward the surface (on the upstroke). “The key was the system of valve leathers, made of cowhide, that captured and released the water from the cylinder,” says Larry Poppy, a docent at the Mid-America Windmill Museum.

Poppy says that his family had a water pump windmill when he was growing up, and that the water was stored in a stock tank in a special stock-tank-sized room on the second floor of the house. “That was our drinking water,” he says. “It had to be partially uncovered so the air could get in. My parents put a pan underneath it because in the summer it would sweat, and you didn’t want the water sitting there on the floor because it would have rotted through.”

Windmills of varying design were produced in hundreds of facilities all over the Midwest and elsewhere. At one time, there were more than 94 windmill manufacturers of varying size within 80 miles of Kendallville. One of them, Flint, Walling & Co. (later known as Flint & Walling), operated just a few miles from where the museum is now.

“Aermotor, out of Chicago, was considered the Cadillac of windmills,” says Mike Harkey, another museum docent. “They only made three models. Of course, Flint & Walling made 11. It was right up there in quality. Eventually Aermotor moved to Texas, and they’re still around. They’re the only major company left who still makes water pump windmills.”

The business of windmills faltered when electricity and gasoline became cheap—circa World War I—and continued through the Depression. In the late 1930s, rural electrification crashed demand. Manufacturers came out with budget versions of popular models. The Fairbury Windmill Company produced a “New Deal Special.”

During World War II, some windmill manufacturers built war-related products. Afterward, when the market for windmills did not improve, many started turning out other goods, like pipes. Flint & Walling hung on for a while, but stopped making windmills in the 1960s. It still makes pumps.

When energy prices spiked upward in the 1970s, people became interested in windmills again. The three remaining windmill manufacturers—Aermotor, Baker, and Dempster—went from producing a couple hundred windmills per year each to several thousand. More companies started up. One problem was that there were not many trained windmillers left over. Universities began offering courses in windmill technology to meet demand. Around that time, people figured out how to make wind a commercially viable source of electricity, and turbines began to hog the windmill conversation.

Like many old-but-still-useful technologies, water pump windmills continue to be employed in various niche contexts, often small-scale and rural, sometimes for projects off-grid. Taylor Schafer, business development manager for Aermotor, says one of the company’s major markets is ranchers who use them to water livestock. Aermotor’s current model, the 802, is nearly identical to the classic Aermotor 702. “Our parts are still interchangeable with the 702 mill,” Schafer says. “The design is basically unchanged since 1933.”

One of the Mid-America Windmill Museum’s prized items is a restored twelve-foot wooden windmill known as the Original Star. The Star was patented in 1878 by Flint & Walling, and set the tone for subsequent Flint & Walling models. It turned counterclockwise, unlike other windmills at the time. The Original Star was painted white with red tips on the blades and red and blue stars on the vane, and soon became one of the most popular wooden windmills in use on the Great Plains.

The Original Star and other windmills at the museum, including the rest of the Flint & Walling fleet, have been put out to pasture. None of them are actually doing any pumping anymore. Many of their wheels are locked in position for maintenance reasons, but a few still spin idly with the wind, recalling an era of westward expansion and agricultural development—history in action.

Follow us on Twitter to get the latest on the world's hidden wonders.

Like us on Facebook to get the latest on the world's hidden wonders.

Follow us on Twitter Like us on Facebook